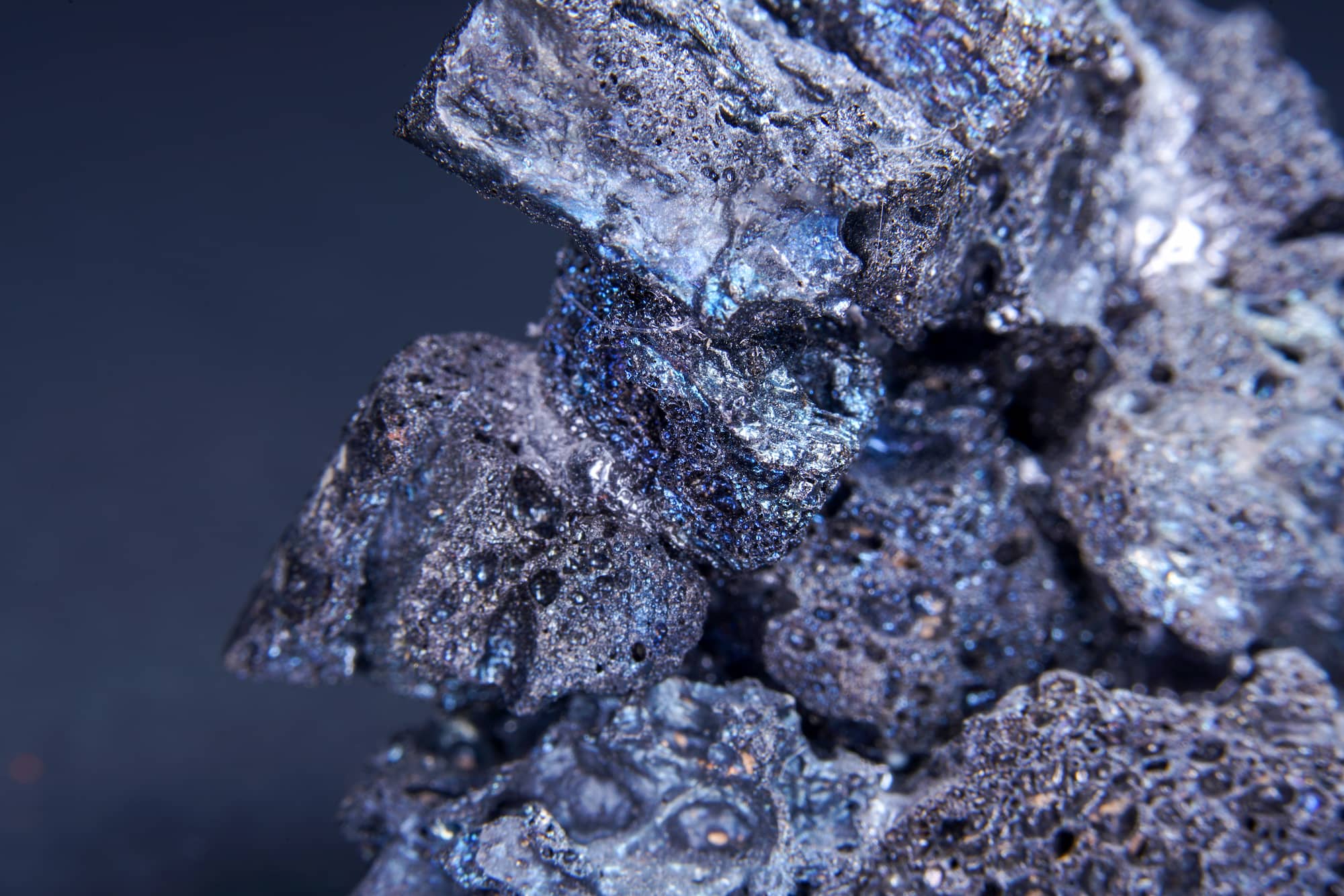

In today’s tech-driven world, electronics are indispensable. From smartphones to electric cars, these devices rely on rare earth metals. These metals are essential for modern technology. With the increasing demand for electronics, recycling rare earth metals has never been more critical. Let’s explore what rare earth metals are, where they come from, and why recycling them is so important.

What are Rare Earth Metals?

Rare earth metals, also known as rare earth elements (REEs), are a group of 17 chemical elements. They have unique magnetic, luminescent, and electrochemical properties. These properties make them crucial for advanced electronics and green technologies.

Where Do They Come From?

Rare earth metals are not rare in terms of their abundance in the Earth’s crust. However, they are often dispersed, making extraction and processing difficult. Most rare earth metals are mined in China, which provides about 85% of global production.

Other sources include:

- The United States

- Australia

- Several African nations

The mining and refining processes can be environmentally harmful, involving habitat destruction and pollution.

Examples

Some common rare earth metals include:

- Neodymium: Used in powerful magnets for wind turbines and electric vehicles.

- Lanthanum: Found in camera lenses and batteries.

- Europium: Used in phosphorescent coatings for TV screens and LED lights.

Other examples are cerium, gadolinium, and dysprosium, each important in various high-tech applications.

Why Recycle These Rare Earth Metals?

Recycling rare earth metals is crucial for several reasons. The extraction and processing are energy-intensive and environmentally damaging, leading to habitat destruction, water pollution, and toxic waste. Recycling reduces the need for new mining operations, minimizing these impacts.

Recycling also helps conserve finite resources, ensuring they are available for future generations. Additionally, it can stabilize supply chains and reduce dependence on foreign sources, mitigating potential supply disruptions and price volatility.

What Products Use These Metals?

Rare earth metals are integral to many electronics and high-tech devices. Here are some key examples:

Computers

Rare earth metals are used in various computer components, including:

- Hard Drives: Neodymium magnets enable data storage and retrieval.

- Screens: Contain rare earth elements for display quality.

- Processors and Memory Modules: Depend on rare earth metals for efficient operation.

TVs

Vibrant TV screen colors are thanks to rare earth metals like:

Europium: Produces red hues.

Yttrium: Helps create green hues.

Other Elements: Contribute to blue hues and overall display quality.

Cars

Electric and hybrid vehicles use rare earth metals in several ways:

- Motors: Neodymium magnets are essential for electric vehicle motors.

- Batteries: Lanthanum is a key component in battery technology.

- Catalytic Converters: Rare earth elements reduce emissions from internal combustion engines.

Phones & More

Smartphones and tablets contain several rare earth metals:

- Speakers and Microphones: Neodymium is used for high-quality sound.

- Magnets: Dysprosium enhances durability.

- Components: Rare earth elements enable miniaturization and functionality.

The Environmental Impact of Rare Earth Mining

The environmental impact of rare earth metal mining is significant. Mining involves removing large amounts of earth and rock, which often leads to deforestation and ecosystem destruction. Refining processes use harsh chemicals, contaminating water supplies and creating toxic waste.

Recycling offers a more sustainable alternative. It reduces the need for new mining operations and lessens environmental damage. It also lowers the carbon footprint associated with these metals.

Economic Benefits of Recycling Rare Metals

Recycling rare earth metals is also economically beneficial. Mining and refining are costly, and prices are likely to increase as resources become scarcer. Recycling recovers valuable materials at a lower cost.

For businesses, recycling can provide financial incentives. Many governments offer tax breaks and subsidies for recycling programs. Consumers can also benefit by trading in old electronics for cash or discounts on new products.

The Future of Rare Earth Metal Recycling

The future of rare earth metal recycling looks promising. Technological advancements are making recycling more efficient. Researchers are developing new extraction methods, including:

- Bioleaching: Using bacteria to release metals from electronic waste.

- Ionic Liquids and Supercritical Fluids: These selectively dissolve rare earth metals from complex mixtures.

As demand for these metals grows, recycling will play a critical role in meeting global needs.

How to Recycle These Products with Great Lakes Electronics Corporation

Great Lakes Electronics Corporation (GLEC) is dedicated to responsible recycling. Our program recovers rare earth metals from a variety of electronic devices. Here’s how our process works:

- Schedule a Pickup: Businesses with large quantities can arrange a pickup with GLEC. Contact us to schedule a convenient time.

- Drop-Off Locations: For smaller amounts, drop off your electronics at one of our designated locations.

- Data Security: We ensure data security by thoroughly wiping and destroying devices.

- Recycling Process: Collected electronics are carefully dismantled. Rare earth metals are extracted using advanced techniques and reintroduced into the supply chain.

By choosing GLEC, you’re helping to protect the environment and contributing to a more sustainable future. Together, we can make a difference by recycling rare earth metals and keeping them out of landfills.